Mashiinnada Cabbirka Isku-dubbaridka (CMMs) - 3D Cabbiraadda Guryaha Korontada

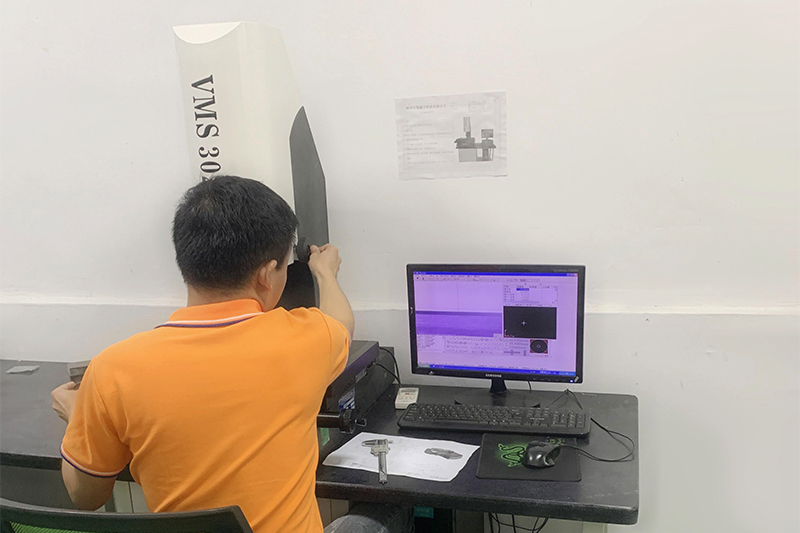

Sidoo kale loo yaqaan 3 - Mashiinnada Cabbirka Cabbirka (CMMs), CMM-yadayadu waa linchpin ee nidaamka kormeerka. Sida ka muuqata sawirka hoose, waa aalado aad u sax ah oo awood u leh inay cabbiraan cabbirka qayb ka mid ah saxnaanta heerka-micron.

CMM-yadu waxay ka helaan codsiyo ballaaran oo ku baahsan warshadaha kala duwan, laga bilaabo hawada hawada ilaa caafimaadka. Hawada sare, waxaa loo shaqeeyaa inay kormeeraan qaybaha muhiimka ah sida marawaxadaha marawaxadaha, iyaga oo hubinaya in xitaa cabbirada ugu yar ay ku jiraan dulqaadka la cayimay. Dhinaca caafimaadka, waxay xaqiijiyaan saxnaanta qalabka qalliinka iyo qaybaha la geliyo

| Tilmaamid | Faahfaahin |

| Cabbirka Range | [X] mm (Dheer) x [Y] mm (Balac) x [Z] mm (Dheer), la qabsan kara cabbirro kala duwan |

| Saxnimada | Ilaa ± 0.001 mm, oo bixisa cabbirro aad u sax ah |

| Noocyada baaritaanka | Ku qalabaysan taabashada - kicinta baadhista cabbiraadda guud iyo baadhista iskaanka ee sifaynta dusha adag |

| Waafaqsanaanta Software | Waxay la midaysaa warshadaha - software metrology hormuudka u ah falanqaynta xogta iyo warbixinta |

Mashiinnada Cabbirka Isku-dubbaridka (CMMs) - 3D Cabbiraadda Guryaha Korontada

Isbarbardhigga indhaha ayaa lagama maarmaan u ah kormeerka xiriir la'aanta ee qaybaha. Sawirku wuxuu muujinayaa mabda'a shaqada ee isbarbardhigga indhaha, halkaasoo qaybta la weyneeyo oo lagu saadaaliyo shaashadda si loo cabbiro.

Kuwani waxay si gaar ah faa'iido ugu leeyihiin warshadaha elektiroonigga ah, halkaas oo qaybaha yaryar iyo kuwa qallafsan ay u baahan yihiin in la eego. Tusaale ahaan, waxaa loo isticmaali karaa in lagu cabbiro cabbirrada isku-xireyaasha-yar-yar ama toosinta raadadka guddiga wareegga. Qalabka - iyo - warshadaha dhinta, isbarbardhigga indhaha ayaa loo isticmaalaa si loo hubiyo saxnaanta caaryada iyo dhinta.

| Tilmaamid | Faahfaahin |

| Range Weyneynta | Laga bilaabo [Min magnification]x ilaa [Max magnification]x, lagu hagaajin karo cabbirrada qaybaha kala duwan iyo shuruudaha kormeerka |

| Xallinta Sawirka | Sawir-qaadista xallinta sare, oo u oggolaanaysa muuqaal cad oo tafaasiil fiican |

| Cabbirka Saxnaanta | ± 0.005 mm cabbirada toosan, hubinta natiijooyin la isku halayn karo |

| Nidaamka Iftiinka | Tilmaamo doorsooma - xoojinta iyo iftiinka xagal badan si kor loogu qaado muuqaalka qayb |

Cabbiraadaha Dhererka Dijital ah - Cabbiraadaha Toosan ee Saxda ah (2.5D Projector)

Qiyaasaha dhererka dhijitaalka ah, oo badanaa loo yaqaan 2.5 - Qalabka Cabbirka, ayaa door muhiim ah ka ciyaara habka kormeerkayaga. Sawirka hoose wuxuu muujinayaa cabbirka dhererka dhijitaalka ah ee la isticmaalayo, oo cabbiraya dhererka qalabka shaqada si sax ah.

Qiyaasahan waxaa si weyn loogu isticmaalaa goobaha wax soo saarka si loo cabbiro dhererka, qoto dheer, iyo tallaabada - dhererka qaybaha. Waxay si gaar ah qiimo ugu leeyihiin wax soo saarka saxda ah - qaybaha mashiinada, sida kuwa laga helo warshadaha baabuurta iyo semiconductor.

| Tilmaamid | Faahfaahin |

| Cabbirka Range | [Dhererka da'da yar] - [dhererka ugu badan] mm, oo ku habboon dherer ballaaran oo qayb ah |

| Saxnimada | ± 0.01 mm, oo bixisa cabbirro toosan oo la isku halayn karo |

| Nooca Muujinta | Muujinta dhijitaalka ah ee akhriska fudud iyo duubista xogta |

| Xulashada Baarista | Lagu heli karo talooyinka baaritaanka kala duwan ee noocyada kala duwan ee dusha sare |

Tijaabada Adag

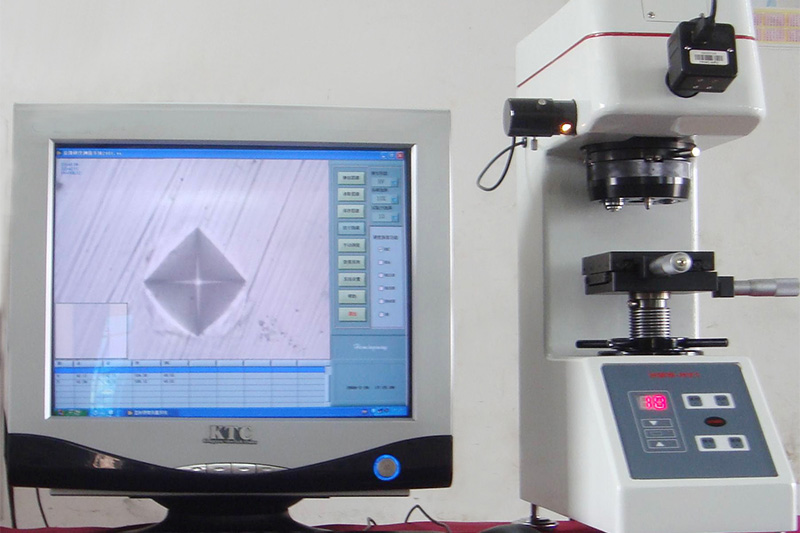

Tijaabada adkaanta waxay lama huraan u tahay hubinta tayada agabka loo isticmaalo hannaan-mashiinka. Sawirka hoose wuxuu muujinayaa tijaabiye adkaanta oo loo isticmaalo in lagu cabbiro adkaanta muunada birta

Warshadaha biraha, tijaabinta adkaanta waxay ka caawisaa xaqiijinta tayada alaabta ceeriin iyo qaybaha dhammaatay. Tusaale ahaan, wax soo saarka qalabka, tijaabinta adkaanta waxay hubisaa in maaddadu ay u adkeysan karto culeysyada sare iyo cadaadiska inta lagu jiro hawlgalka. Waxaan isticmaalnaa noocyada kala duwan ee tijaabiyeyaasha qallafsanaanta, oo ay ku jiraan Rockwell, Brinell, iyo Vickers, si aan u dejino agabyo kala duwan iyo shuruudaha imtixaanka.

| Tilmaamid | Faahfaahin |

| Daboolista Miisaanka Adag | Rockwell: A, B, C miisaanka; Brinell: Miisaanka HBW; Vickers: miisaanka HV |

| Tijaabada Xoogga Range | Xoogaga tijaabinta la hagaajin karo si ay ugu habboonaato heerarka adag ee walxaha kala duwan |

| Noocyada soo gelida | Lagu qalabeeyay indentors ku haboon miisaan kasta oo adag |

| Saxnimada | Cabbiraadaha saxsanaanta sare, gudaha ±[X] unugyo adkaanta iyadoo ku xiran cabbirka |

Tijaabooyinka Roughness Surface

Qalafsanaanta dusha sare waa arrin muhiim u ah arjiyada badan, iyo tijaabiyeyaasha dusha sare ee qallafsanaantooda waxaa loogu talagalay inay cabbirkan si sax ah u cabbiraan. Sawirku wuxuu muujinayaa tijaabiye qallafsanaanta oogada oo la isticmaalayo, isaga oo iskaan ka eegaya oogada qayb la farsameeyay

Warshadaha sida baabuurta iyo wax soo saarka, qallafsanaanta dusha sare waxay saameyn kartaa waxqabadka iyo adkeysiga qaybaha. Tusaale ahaan, qaybaha matoorka, dhammayn sax ah oo dusha sare ah ayaa yarayn kara isku dhaca waxayna kor u qaadi kartaa waxtarka. Tijaabiyayaashayada qallafsanaanta dusha sare waxay cabbiri karaan cabbirro qallafsanaan oo kala duwan, sida Ra (qiyaasta celceliska xisaabta ee astaanta la qiimeeyay) iyo Rz (celcelis ahaan dhererka shanta sare ee ugu sarreeya iyo shanta dooxood ee ugu hooseeya ee dhererka qiimaynta).

| Tilmaamid | Faahfaahin |

| Cabbirka Range | Ra: [Qiimaha Min Ra] - [Max Ra qiimaha] µm, oo ku habboon dhammaystir ballaaran oo dusha sare ah |

| Nooca Sensor | Dareemayaasha stylus-ka saxda ah ee sarreeya |

| Dhererka Muunada | Dhererka muunad la hagaajin karo si loo buuxiyo heerarka warshadaha kala duwan |

| Soo-saarka Xogta | Waxay soo saari kartaa xogta qaabab kala duwan si ay si sahlan ula dhexgalaan nidaamyada tayada tayada |

Microscopes

Mikroskoobyada ayaa qiimo weyn u leh in la baaro faahfaahinta daqiiqadaha ee dusha qaybaha. Sawirka hoose waxa uu muujinayaa mikroskoob loo isticmaalo in lagu baaro qayb marka la wayneeyo

Warshadaha elektiroonigga ah iyo warshadaha dahabka, mikroskoobyada waxaa loo isticmaalaa in lagu baaro tayada kala-goysyada alxanka, dhammaadka dusha sare ee biraha qaaliga ah, iyo daacadnimada qaybaha yaryar. Waxay awood u siiyaan kooxdayada kormeerka inay ogaadaan cilladaha iyo cilladaha aan la arki karin indhaha qaawan.

| Tilmaamid | Faahfaahin |

| Range Weyneynta | Laga bilaabo [Min magnification]x ilaa [Max magnification]x, taas oo u oggolaanaysa in si faahfaahsan loo eego heerar kala duwan |

| Nidaamka Iftiinka | Lagu qalabeeyay iftiinka iftiinka LED-ka si ay u muuqato muuqaal cad oo muunad ah |

| Kartida Sawirka | Moodooyinka qaarkood waxay taageeraan sawir qaadista dukumeentiga iyo falanqaynta |

| Hagaajinta diiradda | Isku hagaajinta saxda ah ee diirada saarista fiiqan ee qoto dheer ee kala duwan |

Mikromitirada

Mikrometer-yadu waa aaladaha cabbiraadda saxda ah ee loo isticmaalo qaadista cabbirro toosan oo sax ah. Sawirka hoose wuxuu muujinayaa mikrometer loo isticmaalay in lagu cabbiro dhexroorka qayb cylindrical ah

Waxaa caadi ahaan loo adeegsadaa hawlgallada mishiinada si loo cabbiro dhexroorka ulaha, dhumucda alaabta, iyo guntooda godadka. Mikromitirada waxaa lagu yaqaan saxnaantooda sare waana aalad lagama maarmaan u ah wax kasta oo sax ah - jawi wax soo saar

| Tilmaamid | Faahfaahin |

| Cabbirka Range | [Cabirka Min] - [Cabirka ugu badan] mm, oo lagu heli karo noocyo kala duwan oo codsiyo kala duwan |

| Saxnimada | ± 0.001 mm, oo siinaya cabbirro toosan oo aad u qumman |

| Naqshada Anvil iyo Spindle | Saxsanaanta - anvils-ka dhulka iyo dunta loo isticmaalo cabbirro joogto ah oo la isku halayn karo |

| Habka qufulka | Lagu qalabeeyay habka qufulka si cabbirka loogu hayo meesha |

Calipers

Calipers waa qalab wax lagu cabbiro oo kala duwan oo loo isticmaali karo in lagu cabbiro cabbirrada gudaha, dibadda, iyo qoto dheer ee qaybaha. Sawirka hoose wuxuu muujinayaa caliper dhijitaalka ah oo loo isticmaalay in lagu cabbiro ballaca qayb.

Waxaa si aad ah loogu isticmaalaa warshado kala duwan, laga bilaabo alwaax-samaynta ilaa biraha la sameeyo. Calipers waxay bixiyaan hab ku habboon oo sax ah oo lagu qaado cabbirro degdeg ah inta lagu jiro habka wax soo saarka.

| Tilmaamid | Faahfaahin |

| Range Weyneynta | Laga bilaabo [Min magnification]x ilaa [Max magnification]x, taas oo u oggolaanaysa in si faahfaahsan loo eego heerar kala duwan |

| Nidaamka Iftiinka | Lagu qalabeeyay iftiinka iftiinka LED-ka si ay u muuqato muuqaal cad oo muunad ah |

| Kartida Sawirka | Moodooyinka qaarkood waxay taageeraan sawir qaadista dukumeentiga iyo falanqaynta |

| Hagaajinta diiradda | Isku hagaajinta saxda ah ee diirada saarista fiiqan ee qoto dheer ee kala duwan |

Ku xidh Cabiraadaha

Cabiradaha furaha waxaa loo isticmaalaa in lagu hubiyo dhexroorka godadka iyo godadka. Sawirka hoose waxa uu tusinayaa jaangooyooyin fiilo ah oo loo istcmaalayo in lagu baaro godka shaqada

Marka la soo saarayo qaybaha ay ka midka yihiin dhululubada mishiinada, valves-ka, iyo tuubooyinka, cabirada furku waxay xaqiijiyaan in dhexrooryada guduhu ay buuxiyaan dulqaadka la cayimay. Waa qalab fudud oo aad waxtar u leh oo lagu xakameynayo tayada daloolka - cabbirada la xiriira

| Tilmaamid | Faahfaahin |

| Qiyaasta Dhexroorka Dhexroorka | Dhexroorka ugu yar - [dhexroorka ugu badan] mm, oo lagu heli karo cabbirro kala duwan si ay ugu dhigmaan dhexroorka daloolka kala duwan |

| Heerka dulqaadka | Waxaa loo soo saaray fasallo dulqaad gaar ah, sida H7, H8, iwm., si loo xaqiijiyo ku habboonaanta saxda ah |

| Qalabka | Laga sameeyay bir adag oo tayo sare leh si loogu adkaysto oo loo xidho caabbinta |

| Dhamaystirka dusha sare | Dhammays wanaagsan oo dusha sare ah si looga hortago waxyeellada qaybta la baarayo |