Awoodaha leexashada CNC oo dhamaystiran

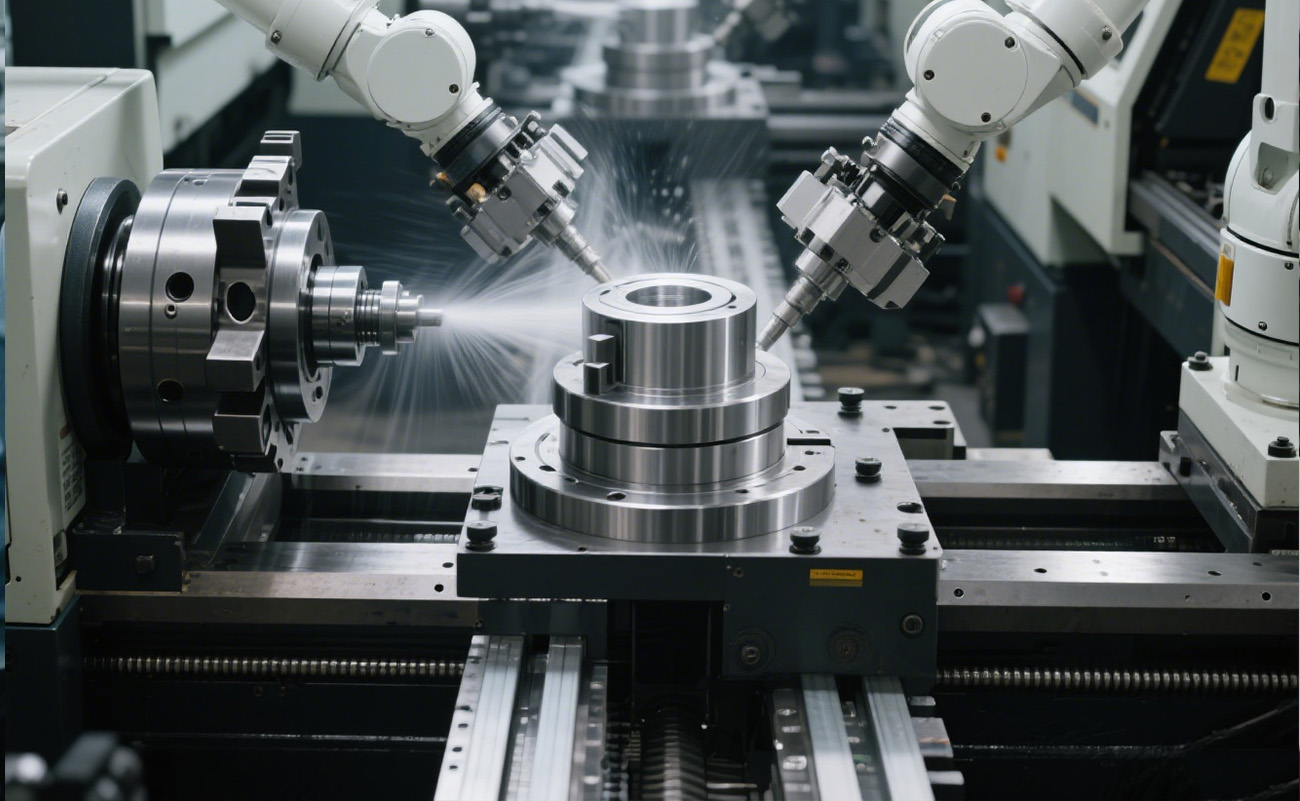

Shaxda 1:Qalabka Wareega ee CNC iyo Tilmaamaha Farsamada.

| Qaybta | Faahfaahin | Tilmaamaha Muhiimka ah |

| Noocyada Mashiinnada | CNC Slant - Xarumaha Sariirta: Doosan Puma 5100, Hyundai Wia Lynx 220LSY | Isku geynta qalabka leexinta: 30+ unug horumarsan |

| Qiyaasta agabka | Biraha: | Shahaadooyinka agabka: Warbixino raadraac oo buuxa ayaa jira |

| Range Processing | Dhexroorka ugu badan ee leexashada: 500 mm | Qalabka Tooska ah: Samee wax-shiidid, qodid, iyo hawlgalo taabasho oo hal habayn ah |

| Dulqaadka saxda ah | Wareega: ≤ 0.001 mm | Qalabka Kormeerka: Zeiss Contura CMM oo sax ah ± (1.5 + L/350) μm |

| Boostada - Processing | Dhamaystirka dusha sare: | Heerarka Warshadaha: ASTM B580 (plating), Boeing BAC 5616 (anodizing) |

Codsiyada Warshadaha iyo Daraasadaha Kiis

Shaxda 2:Qaybaha caadiga ah iyo Guulaha Farsamada.

| Warshadaha | Qaybaha Guud | Tilmaamaha Farsamada |

| Hawada hawada | Mashiinnada marawaxadaha, Bolts Gear-ka-soo-dejinta Ulaha Dhaqdhaqaaqa, Matoorada Koritaanka | Qalabka: Mashiin laga sameeyay Ti - 6Al - 4V oo leh dulqaad cabbir ah ± 0.003 mm Dhammaystirka dusha sare: Lagu gaadhay Ra 0.4 μm dusha sare ee xajmiyeedka muhiimka ah U hoggaansanaanta: Gudubtay daalka FAA iyo shuruudaha tijaabada walaaca |

| Qalabka Caafimaadka | Maqaarka Lafaha (Skru, biinanka) Gacan-qabashada Qalabka Qalliinka, Cannulas | Qalabka: Tiitanium-ka-caafimaadka (ASTM F136) oo leh daawaynta dusha bayoolojiga ah Saxsanaanta: Dulqaadka xajinta ee gudaha ± 0.001 mm ee isu imaatinka sugan Wax soo saarka qolka Nadiifinta: ISO 13485 deegaan wax soo saar oo waafaqsan |

| Baabuur | Camshafts, gacan-qabsiga Axle Shafts, Falalka Gudbinta | Qalabka: 4140 birta aluminiumka ah oo leh daawaynta kulaylka la demiyay oo dabcay Waxtarka: Hoos u dhaca wakhtiga wareegga wax soo saarka 30% iyadoo la isticmaalayo xawaare sare Mugga: Awood u leh inuu soo saaro 10,000+ shaft bishii |

| Saliidda & Gaaska | Qaybaha Qalabka Downhole Jirridaha Valve, Ulaha bambooyinka | Walxaha: Daxalka - Alloys adkaysi u leh (Inconel, Hastelloy) Feature: Xadhkaha gudaha ee qoto dheer ee la farsameeyay oo leh saamiga L/D> 15:1 Tijaabada: Gudbay NACE MR0175 sulfide stress test |

| Elektrooniga | biinanka isku xirka saxda ah Meesha Heat-kuleelka, Ulaha matoorada yaryar | Qalabka: Naxaas leh dhejis nikkel ah oo loogu talagalay dhaqdhaqaaqa iyo cimri dhererka Saxnaanta: Dulqaadka dhexroorka ± 0.002 mm ee codsiyada ku habboon Dhammaystirka dusha sare: Koronto loo xidhay ilaa Ra 0.8 μm si loo xoojiyey xidhiidhka korantada |

Habka Waxsoosaarka iyo Xaqiijinta Tayada

Nidaamkeena wax soo saarka waxaa loogu talagalay in lagu ilaaliyo heerarka ugu sarreeya ee saxda ah iyo joogtaynta marxalad kasta.

Naqshadeynta Naqshadeynta iyo Qorsheynta Habka

Waxaan ku bilaabaynaa samaynta falanqaynta Nakhshad dhamaystiran ee Wax-soo-saarka (DFM) anagoo adeegsanayna software horumarsan sida SolidWorks iyo CAMWorks. Tani waxay naga caawinaysaa inaan tayaynno dariiqyada aaladaha, xulashada agabyada ugu habboon, iyo naqshadaynta qalabyada gaarka ah si aan u hubinno qayb sugan oo haynta inta lagu jiro mashiinka.

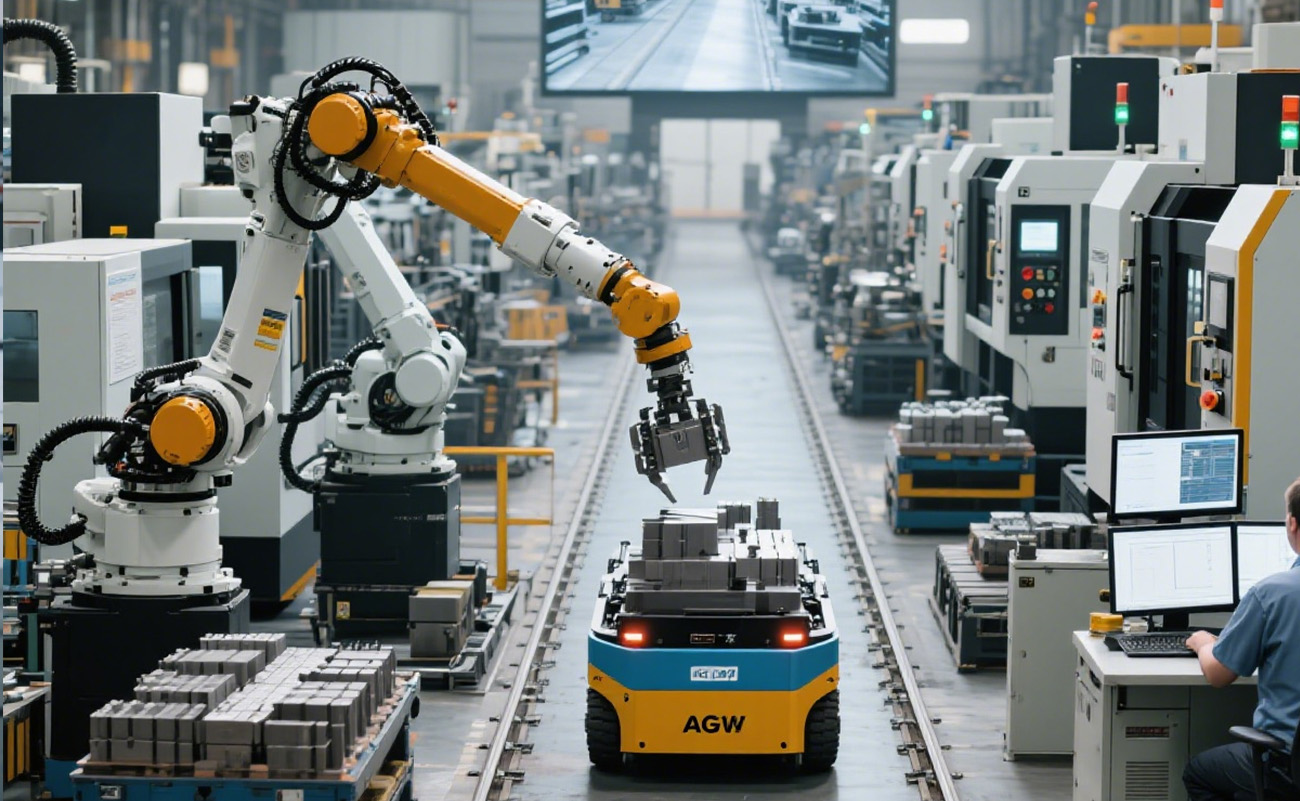

Soo-jeedinta iyo Gudaha CNC Kormeerka

Nidaamkeena farsamaynta otomaatiga ah, oo ay ku qalabaysan yihiin feederiyeyaasha bar iyo robotka, ayaa awood u siinaya wax soo saarka joogtada ah ee qaybo isku mid ah. Dib-u-eegis-wareejinta-wareegga ayaa loo isticmaalaa in lagu cabbiro cabbirrada waqtiga-dhabta ah, taasoo u oggolaanaysa in si degdeg ah wax looga beddelo. Farsamooyinka Xakamaynta Habraaca Tirakoobka (SPC) ayaa lagu dabaqaa si loola socdo cabbirrada mashiinnada muhiimka ah, iyadoo la hubinayo tayada joogtada ah inta wax soo saarka oo dhan.

Kormeerka ugu dambeeya iyo Xakamaynta Tayada

Qayb kastaa waxa ay martaa nidaam kormeer oo adag. Waxaan isticmaalnaa Zeiss Contura Coordinate Measuring Machine (CMM) si aan u samayno cabbirro 3D oo dhammaystiran, annagoo ku xaqiijinayna dhammaan cabbirrada muhiimka ah saxnaan sare. Kormeer muuqaal ah oo 100% ah ayaa sidoo kale la sameeyaa si loo hubiyo cilladaha dusha sare, burburka, iyo tayada dhammaynta. Qaybaha leh shuruudo hawleed gaar ah, waxaanu samaynaa tijaabooyin shaqo oo dheeri ah, sida tijaabinta qulqulka, adkaanta, iyo daalka.

Qiimaha iyo Wakhtiyada Hogaaminta

Shaxda 2:Qaybaha caadiga ah iyo Guulaha Farsamada.

| Nooca Dalabka | Tirada tirada | Waqtiga Hogaaminta | Qodobka Qiimaha |

| Prototyping | 1 - 30 unug | 3-5 maalmood oo shaqo ah | Qiimaha alaabta, kakanaanta, iyo wakhtiga dejinta |

| Mug hooseeya | 30 - 500 unug | 7-12 maalmood oo shaqo ah | Cabbirka dufcada, shuruudaha qalabaynta |

| Wax-soo-saarka guud | 500+ unug | 15-30 maalmood oo shaqo ah | Mugga wax-soo-saarka, wax-soo-saarka muddada-dheer |

ISO 9001: 2015 Nidaamka Maareynta Tayada La Xaqiijiyay

AS9100D U hoggaansanaanta Qaybaha Hawada

ISO 13485 U hoggaansanaanta Soo saarista Aaladaha Caafimaadka

RoHS/REACH Isha Alaabta Awaafaqsan

Qiimaha iyo Wakhtiyada Hogaaminta

Diyaar ma u tahay inaad mashruucaaga nolosha keento? La xidhiidh kooxdayada iibka ee khibradda leh maanta.

Iimayl:sales@xxyuprecision.com

Taleefanka:+86 - 755 - 27460192

Kaliya ku dheji moodooyinkaaga 3D (STEP/IGES) ama sawiro farsamo, waxaanan ku siin doonaa xigasho faahfaahsan 24 saacadood gudahood. Aan ku tusino sababta aan u door bidnay la-hawlgalayaasha CNC ee ganacsiyada adduunka oo dhan.